Бренды

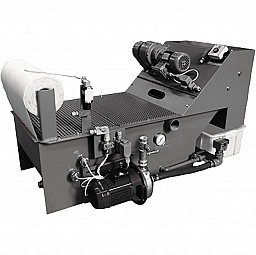

Vacuum band filters StUF

Vacuum band filters StUF

-

Size 50 … 250

-

Filter rating 20 ... 100 µm

-

Filter area 0.5 … 2.5 m²

-

Supply power 100 … 500 l/min

-

Throughput 50 ... 12.000 l/min

- Filter horizontally divided into dirty section and vacuum chamber by punched-hole screen or slotted screen

- Slotted screens optionally in steel or stainless steel, clearance 125 μm to 5 mm

- Removal slope with adjusted discharge height (standard 1200 mm)

- Double-stranded chain with scraper angle (standard t = 40 mm)

- Drive station with geared motor IP 44, insul. class B

- Vacuum monitoring for discontinuous filter operation

- Regeneration tank or clean tank

- Automatic valve with solenoid valve for regeneration

- Filter medium bracket with filter medium from 50 to 250 g/m2

- Transfer pump as filter or filter/feed pump

- Optionally equipped with reel for used fleece

- Dirt tank

Full-flow filtration of chip- and abrasion-contaminated oils or emulsions with endless band or consumable fleece.

The band filters are particularly used in case of high requirements on the filtration fineness particularly at machine tools, in the chemical industry and in washing systems.

The performance lies at 50 - 12000 l/min. Numerous optional parts such as dirt tank mobile or for forklift transport and pre-separators as solenoid or slotted screen are available.

Design as one- or multi-pump system.

Field of application

Filtration of emulsions, solutions, waters, oils up to 200 mm2/s930 SUS (approx. 30° C) with filtration fineness of approx. 20 – 100 μm according to filter medium quality and according to filter cake set-up possible.

Standard set-up

Function

One-pump system

The liquid to be filtered reaches the dirt section of the filter and is sucked out of the underpressure chamber by the filter supply pump; simultaneously, the supply of the actuator is ensured.

The contamination in the medium is held back by the filter medium which rests on the filter bottom and, even after a short time, forms a filter cake which now provides for the actual fine filtration in the micro range. When the liquid flows through, the filter cake causes resistance which is permanently monitored in the suction piece of the production pump. When a max. underpressure of 0.3 bar is reached, the regeneration is initiated. The automatic fitting opens the connection to the regeneration tank and unloads the underpressure chamber. During the following cycle, the production pump sucks in cleaned liquid from the regeneration tank and supplies the actuator. The integrated scraper equipment clocks in the chip rejector direction and draws in approx. 20 cm new filter medium. The regeneration cycle is completed, the automatic fitting closes, the production pump sucks through the fiber fleece again. The filter cake on the removal slope outside the liquid level gets dry and is removed as soon as it is dry enough to be shoveled out.

Multi-pump system

Same function as described above, however the filter pump does no longer deliver to the actuator. It is only responsible for maintaining the filter circuit to the clean tank. During the regeneration cycle, the filter pump is switched off. One or several delivery pumps (a max. delivery pressure of up to 100 bar is possible) displace the filtered medium from the clean tank to the actuator.